leading Exporter of Nickel 200 / Nickel 201 / Nickel 200 / Nickel 201 Suppliers Exporters Stockist India

Anand Metals (India) Stockist manufacturers and suppliers of Nickel 200 / Nickel 201, Exporter of Nickel 200 / Nickel 201 / Nickel 200 / Nickel 201 India

Nickel 200 / Nickel 201 Mumbai, Bengaluru, Chennai, New Delhi, Pimpri-Chinchwad, Seoul, Hyderabad, Singapore, Pune, Kolkata, Gurgaon, Navi Mumbai, Ahmedabad, Calgary, Noida, Vadodara, Coimbatore, Thane

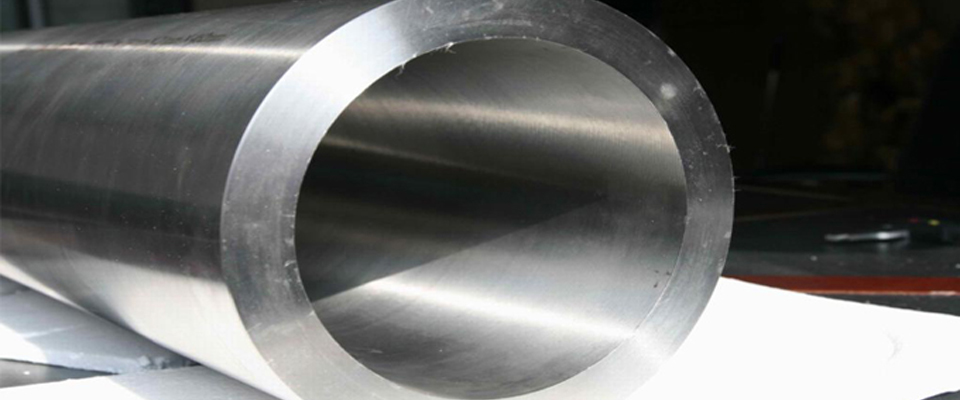

Nickel 200/201

Nickel 200/201

Common Trade Names:

Nickel 200 or Ni 200 is 99.6% commercially pure wrought nickel. Nickel 200 has excellent resistance to many corrosive environments and good mechanical properties . Other useful features of Nickel 200 are its magnetic and magnetostrictive properties, low gas content,high thermal and electrical conductivities and low vapor pressure. Nickel 201 or Ni 201 is the low-carbon version of Nickel 200 . The Nickel 201 has the similar characteristics as the Nickel 200

Available Product Forms:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| Standard | Nickel 200 | Nickel 201 |

|---|---|---|

UNS |

N02200 |

N02201 |

Werkstoff Nr. |

2.4066 |

2.4068 |

Chemical Composition

| Nickel 200 | Nickel 201 | |

| Ni | 99.0 min | 99.0 min |

| Fe | 0.4 max | 0.4 max |

| C | 0.15 max | 0.02 max |

| Mn | 0.35 max | 0.35 max |

| Si | 0.1 max | 0.2 max |

| Cu | 0.25 max | 0.25 max |

| Mg | 0.15 max | |

| Ti | 0.1 max | |

| S | 0.01 max | 0.01 max |

Mechanical Properties

| Density | 8.9 g/cm3 |

| Melting Point | 1446 °C (2635 °F) |

| Tensile Strength | Psi – 67000 , MPa – 462 |

| Yield Strength (0.2%Offset) | Psi – 21500 , MPa – 148 |

| Elongation | 45 % |

Specification for Nickel Alloys 200 / 201 include the following:

Rod and Bar: ASTM B 160; ASME SB 160, DIN 17752, ISO 9723, VdTÜV 345.

Pipe and Tube: ASTM B 161; ASME SB 161, ASTM B 163; ASME SB 163, ASTM B 725; ASME SB 725, ASTM B730; ASME SB 730, ASTM B 751; ASME SB 751, ASTM B775; ASME SB 775, ASTM B 829; ASME SB 829, DIN 17751, ISO 6207, BS 3074 (NA12), VdTÜV 345.

Plate, Sheet & Strip: ASTM B 162/ ASME SB 162, DIN 17750, ISO 6208, BS 3072-3073 (NA12), SAE AMS 5553, VdTÜV 345.

Fittings: ASTM B 366/ ASME SB 366

Forgings: ISO 9725, DIN 17754

Chemical Composition: DIN 17740

Wire: DIN 17753, ISO 9724

Anand Metals (India) manufacturers of Nickel 200 / Nickel 201, suppliers of Nickel 200 / Nickel 201, Exporter of Nickel 200 / Nickel 201 / Stockist of Nickel 200 / Nickel 201 India

Please feel free to give your inquiry in the form below. we will reply you soon ::

Contact Us

Address : 5th, 1st Parsiwada, Hira Building,

NanuBhai Desai road, Mumbai - 400 004, Maharashtra, India

Tel : +91 22 66394593, 6659 5681/82

Fax : +91 22 23856627

Email Id : sales@anandmetals.com

Industries We Serve